View Our Frequently Asked Questions

Select a FAQ category to get started

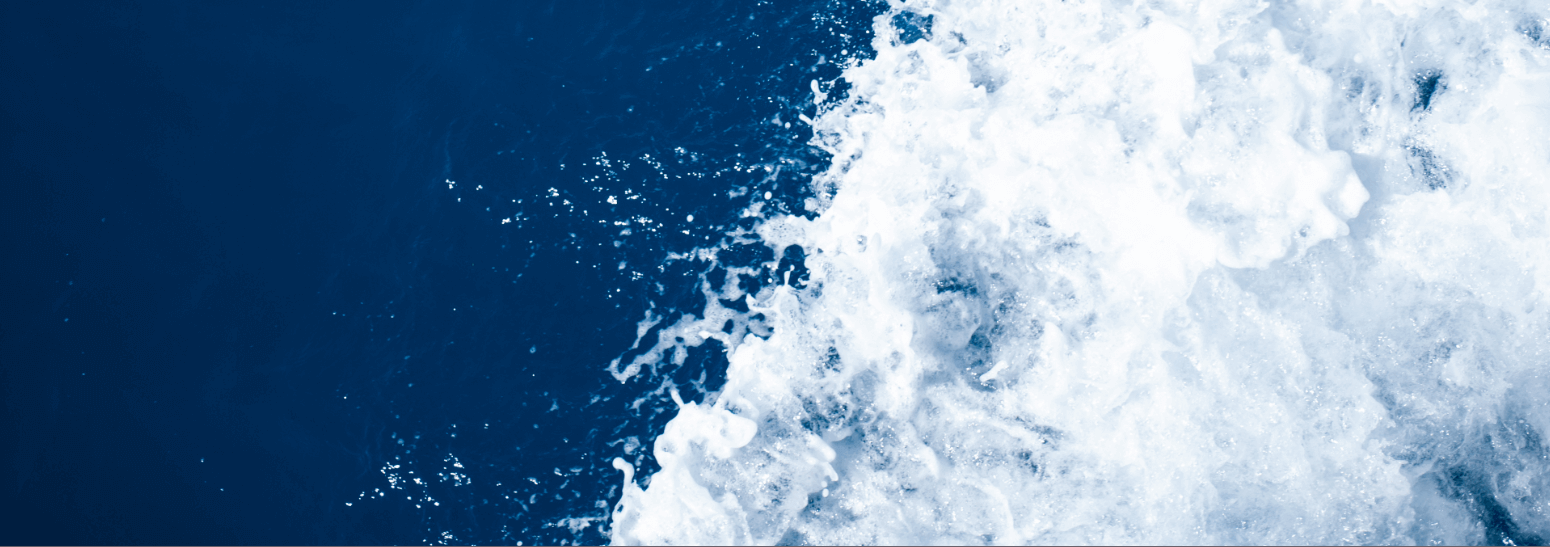

A turbidity curtain is used to contain turbidity (sediment and salt) that is stirred up by construction activities taking place in or near bodies of water, dredging operations and rainwater runoff.

Turbidity curtains are commonly referred to as a turbidity barrier, silt barrier or a silt curtain.

Yes! We manufacture all silt curtains, booms, and baffles in our facility located in Humble, Texas.

Costs are always dependent on the size, application, and duration of the turbidity curtain. We recommend contacting one of our sales representatives, so that they can explain our pricing structure and help you find the best curtain, baffle, or boom for your project.

Yes. We can provide full installation services for turbidity curtains, booms, and baffles.

If your turbidity curtain is exposed to an area with high marine traffic, construction activities, should be inspected daily. Calmer environments can have inspections every several weeks. In the chance of extreme weather, curtains should be removed in advance to avoid risk of damage.

Turbidity curtains are usually made in lengths of 25, 50 or 100 feet. ABASCO can create custom turbidity curtains with varying lengths.

We meet regulations and requirements of the Clean Water Act, National Pollution Discharge Elimination System (NPDES), and any state (DOT) and local regulations.

ABASCO's representatives analyze several factors such as anchor loads, wind, bottom conditions and current directions to determine the amount and placement of anchors needed because it depends on each project's environment.

Usually you want to keep the curtain 1’ off the bottom during Low Mean Tide (LMT). If you need the curtain to touch the bottom it may need to be modified or upgraded.

ABASCO can provide curtains with customized tapered bottoms for adjustment and/or furling lines which can adjust depth while in operation.

Containment Boom is usually used to capture items at the surface, typically to be removed from the water such as oil and trash. Curtains are used to isolate an area, typically allowing sediment to settle in a controlled environment.

Multiple variables can determine which curtain you need such as depth, current, wave height and wind conditions being the primary factors. They are also regulated by government agencies or the contractual requirements.

Multiple variables will determine anchoring requirements just as they are needed to determine the type of curtain but the layout and potential curtain load will have the largest influence.

Anchor Systems are used to secure the curtain along the perimeter. Tow Bridles can secure the ends and for deployment/towing purposes.

The primary purpose of a containment boom is to contain and limit the area which has been impacted by a hydrocarbon or chemical spills. A floating boom's performance is determined based upon buoyancy, roll response and heave response within a given application to contain hydrocarbons or chemicals generally during a spill event. These application factors will better determine which is the right containment boom design and options using several evaluation criteria.

Oil booms mitigate the negative impact to the environment caused by hydrocarbon or chemical spills and also reduce financial impacts through timely cleanup which limits the area exposed to the spill.

The most common types of containment booms are conventional curtain boom, permanent boom, fence boom, air inflated boom, self inflated boom and tidal/shoreline booms.

In accordance with local, state and federal guidelines a containment boom can be used on most bodies of water based upon using the correct boom selection criteria and deployment techniques to properly contain a hydrocarbon or chemical spill.

Several criteria are utilized for proper containment boom selection to include water body classifications (ASTM F1523 or OPA 90) which is based upon wave heights and conditions. These determine the basic physical design requirements including overall boom height and reserve buoyancy. Additional considerations would be a boom's roll response in currents; heave response in waves; freeboard height and skirt depth and forces on the boom which will require a review of oil boom strength.

Oil booms should be cared for in accordance with an operations and maintenance manual where the boom is preferably not exposed to sunlight, harsh weather conditions or rodents which can damage the boom fabric. Additional considerations would be the boom stack height; secured on pallets to avoid abrasion; properly cleaned after deployments and repairs made if any operational damage in accordance with repair kit instructions.

Depending upon deployment requirements, boom accessories can include tow bridles, handles, repair kits, anchor kits, rope, lighted buoys, shoreline anchors, storage boxes, boom reels, deployment rollers or pads and other potential items based upon the location requirements.

Oil spill containment boom effectiveness is based upon a proper evaluation of the location conditions and utilizing the selection criteria for the correct containment boom which includes a review of the float/skirt heights, tensile strength and reserve buoyancy. Following the proper deployment and containment guidelines should result in proper boom containment performance in most cases.

ABASCO Case Studies

Contain construction sediments within each reservoir’s work zones used to provide seismic and hydraulic upgrades at the three reservoirs built between 1888.

Read More

Contain hydraulic dredge site contaminated sediments within several work zones utilizing 3,400’ of double-walled TYPE 3 HD curtains to manage site turbidity.

Read MoreTRUSTED BY