Turbidity Curtains & Silt Curtains

Browse By Type: Type I | Type II | Type III

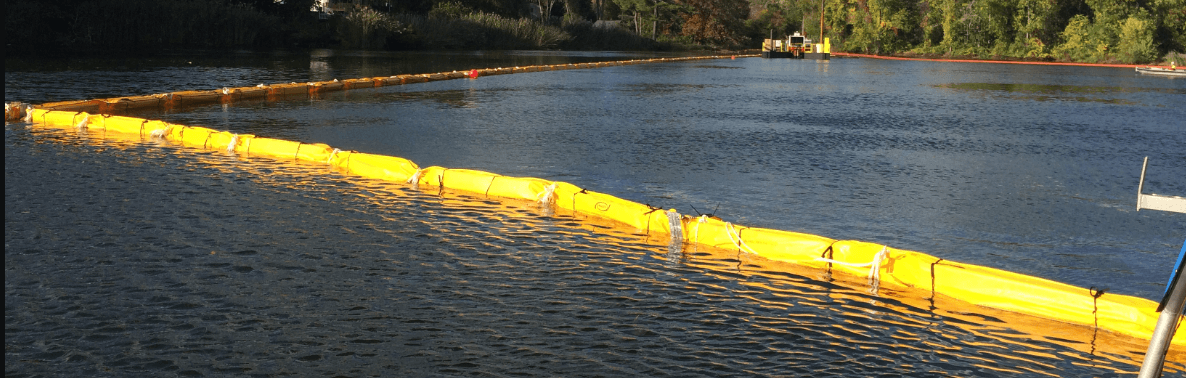

A turbidity curtain, also commonly referred to as a turbidity barrier, silt barrier or a silt curtain, is used to contain turbidity (sediment and silt) that is stirred up by construction activities taking place in or near bodies of water, dredging operations and rainwater runoff. ABASCO floating turbidity curtains have a series of continuous flotation elements along its top and a fabric skirt hanging below the floats.

The skirt is typically long enough to be within one foot of the bottom and can be used to contain various turbidity. Turbidity curtains & silt curtains are usually made in lengths of 25, 50 or 100 ft and those sections are joined to make one continuous containment barrier that encloses a worksite. These silt curtains also come in three different types, which are all dependent on different applications and environmental variables.

Regulations & Requirements

Our turbidity control specialists will help you conform to all regulations and requirements that might apply to your project, including:

- Clean Water Act

- National Pollution Discharge Elimination System (NPDES)

- State (DOT) Requirements

- Local Regulations

Type 1 DOT Turbidity curtain is suitable for use in protected waters where the effects of wind, waves and current are minimal.

Type 2 Turbidity curtains are ideal for silt and sediment control during dredging and marine construction in areas with mild current, wind and wave activity.

Type 3 Turbidity Curtains combine high strength fabric and heavy-duty tension members that are ideal for moderate current, wind and wave activity.

Learn More About ABASCO Turbidity Curtains & Silt Curtains

Applications

ABASCO turbidity curtains have features for various applications including lakes, ponds and other bodies of water. Our materials are of the highest quality and feature reinforcement of all highly stressed areas. We also have furling systems that assist with easy deployment and retrieval. Our specialists will help you select the appropriate curtain grade as well as the optimum installation design for your project, using the following criteria:

- Site conditions and hydrodynamic regime:

- wind

- waves

- current

- water depth

- tides or other changes in water level

- bottom geometry

- bottom composition

- Project duration

- Type of material in suspension

Construction Turbidity Curtain Use

ABASCO turbidity barriers are the ideal solution for any type of construction project, including:

- Dredging

- Bridge construction

- Dam removal and restoration

- Marina/harbor projects (bulkheads, piers, retaining walls)

- Port and terminal projects (groins, dikes, breakwaters)

- Ferry landings

- Pipeline crossings

- Coastal and shoreline restoration and rehabilitation

- Intake construction

Uses for Turbidity Curtains & How They Work

A turbidity curtain sits in the water and traps various sediments from continuing past the barrier. There is also an option to use filtered fabric that lets water pass through, but not the sediment that is contained. Filtering fabrics are the same quality as general turbidity curtains, but they allow for the exchange of water between each side of the barrier, helping to maintain oxygen levels and preventing the water inside the turbidity curtain from becoming stagnant. Common uses include:

- Construction Sites - Silt and dirt sediments from construction move through the air and eventually land in the surrounding water areas. Turbidity curtains sit in the water and stop silt, dirt, or debris from continuing past the barrier, eventually causing the sediment to settle to the bottom.

- Environmental Remediation - Turbidity curtains can also be used in environmental remediation to prevent toxic chemicals and heavy metals from leaving the worksite.

- Marine Life Protection - Turbidity barriers work to control the release of organics in the water column, which at concentrated levels can be toxic to marine life.

Oil Containment

Construction sites can also create hydrocarbons due to dredging operations. In this case, turbidity curtains should be lined with oil sorbent booms parallel to the curtain. This can be anchored directly to the turbidity curtain and will absorb the hydrocarbons before they can reach the curtain.

If there is a possibility of a great amount of hydrocarbons that could be released, it would be beneficial to have a line of oil containment booms inside the turbidity curtain enclosure. ABASCO’s oil containment booms paired with turbidity curtains creates the optimal situation for your construction site.

Turbidity Curtain Frequently Asked Questions

Multiple variables can determine which curtain you need such as water depth, current, wave height and wind conditions being the primary factors. They are also regulated by government agencies or contractual requirements.

Multiple variables will determine anchoring requirements just as they are needed to determine the type of curtain but the layout and potential curtain load will have the largest influence.

ABASCO's representatives analyze several factors such as anchor loads, wind, bottom conditions and current directions to determine the amount and placement of anchors needed because it depends on each project's environment.

Usually, you want to keep the curtain 1’ off the bottom during Low Mean Tide (LMT). If you need the curtain to touch the bottom it may need to be modified or upgraded.

ABASCO can manufacture custom-designed curtains with customized tapered bottoms for adjustment and/or furling lines which can adjust depth while in operation.

CASE STUDIES

Contain construction sediments within each reservoir’s work zones used to provide seismic and hydraulic upgrades at the three reservoirs built between 1888.

Read More

Contain hydraulic dredge site contaminated sediments within several work zones utilizing 3,400’ of double-walled TYPE 3 HD curtains to manage site turbidity.

Read More